AdiLogiX:Where Industrial Intelligence Meets Interface.

Contact Us

AdiLogiX: delivers seamless OPC UA communication.

Contact Us

AdiLogiX:Where Industrial Intelligence Meets Interface.

SCADA Software for Industrial Automation

AdiLogiX is a next-generation SCADA platform designed for real-time performance, no-code configuration, and seamless PLC integration via Modbus TCP/IP, RS-485(ASCII/RTU), OPC UA, Siemens S7, Omron FINS, BACnet and MQTT Gateways. It features intelligent data polling, virtual tag creation, intuitive alarm setup, historical logging, and a responsive dashboard builder—all powered by a high-speed runtime engine. From device discovery to live monitoring, AdiLogix simplifies industrial automation with drag-and-drop tools, secure multi-user access, and one-click deployment.

Architecture

Why Choose AdiLogiX SCADA

No-Code, Visual Configuration

With Adilogix, configuring your SCADA system is easier than ever. The platform offers a fully visual, drag-and-drop interface to set up PLCs, define tags, design dashboards, and manage alarms—no programming required. Spend less time coding and more time optimizing your operations.

Seamless Multi-Protocol Integration

Adilogix supports Modbus TCP/IP, RS-485(ASCII/RTU), OPC UA, Siemens S7, Omron FINS, BACnet and MQTT Gateways allowing seamless communication with a wide range of PLCs and devices. Whether you’re running a small plant or a complex multi-vendor network, Adilogix ensures everything connects effortlessly.

OPC UA Integrated in AdiLogiX

Adilogix comes with built-in OPC UA integration, allowing seamless, secure communication with a wide range of industrial devices and controllers. With native support for OPC UA’s data modeling and encrypted communication, Adilogix reliably connects to PLCs, sensors, and automation systems without additional middleware. This integration ensures real-time data flow, easy scalability, and a unified, standardized interface for managing complex industrial operations efficiently.

Omron FINS & Siemens S7 Connectivity

Native Omron FINS & Siemens S7 Support Seamless integration, monitoring, and control of Omron and Siemens PLCs across all AdiLogiX modules

SIMATIC S7 family PLCs

- SIMATIC S7-1200 (1211, 1212, 1214, 1215, 1217),

- SIMATIC S7-1500

- SIMATIC S7-300

- SIMATIC S7-400 (412, 414, 416, 417 )

- SIMATIC S7-200

Omron Fins protocol supported PLCs

- C-series: C200, C500, C1000, C2000

- CV-series: CV500, CV1000, CV2000

- CVM1-series: CVM1-CPU01, CVM1-CPU11, CVM1-CPU21

- CS1-series: CS1G, CS1H, CS1D

- CJ1-series: CJ1G, CJ1H, CJ1M

- CJ2-series

- CP-series: CP1E, CP1H, CP1L, CP2E

- NX/NJ-series

- NSJ-series

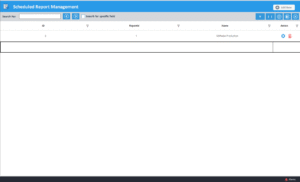

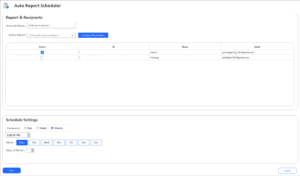

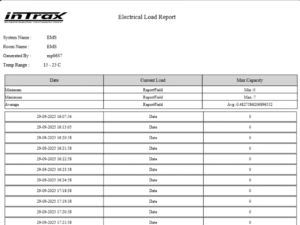

Automatic Report Generation

AdiLogix offers smart Automatic Report Generation that converts real-time plant data into clear, accurate, and audit-ready reports—without manual work. From trends and alarms to batch records and performance logs, reports are created instantly or on schedule and shared automatically with your team. Fast, reliable, and compliance-ready, AdiLogix keeps every process documented and every decision data-driven.

User-driven report generation:

- Daily

- Weakly

- Monthly

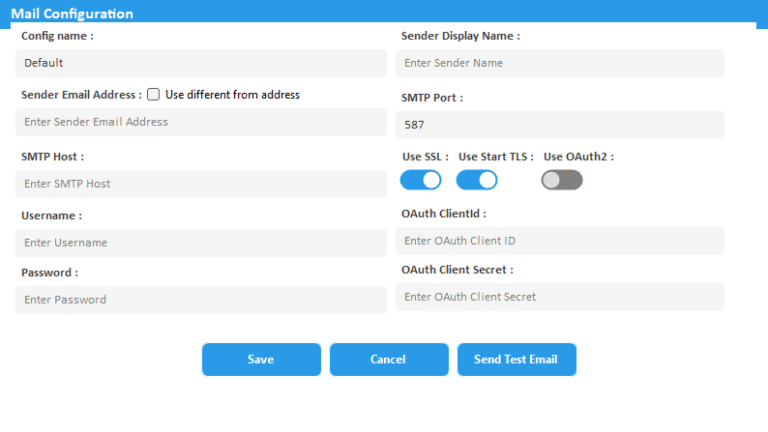

AdiLogix automatically sends generated reports instantly through Telegram, WhatsApp, and Email.

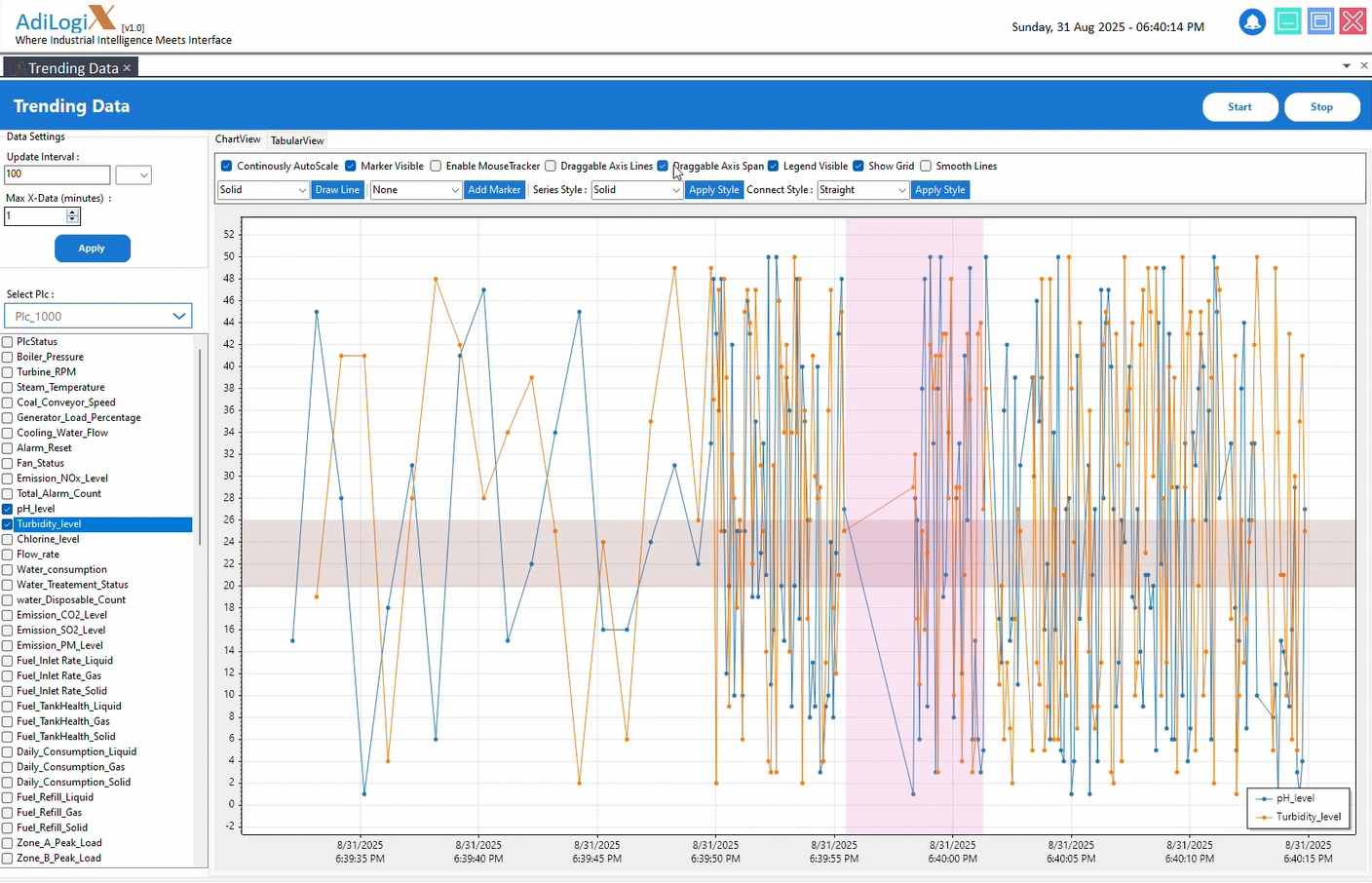

Real-Time, Reliable Performance

At its core, Adilogix features a powerful runtime engine built for speed and reliability. It handles continuous data acquisition, real-time tag updates, alarm processing, and historical logging—delivering stable, 24/7 operation for mission-critical environments.

Ultra-low latency: real-time performance from 100 ms onwards to cater your business needs

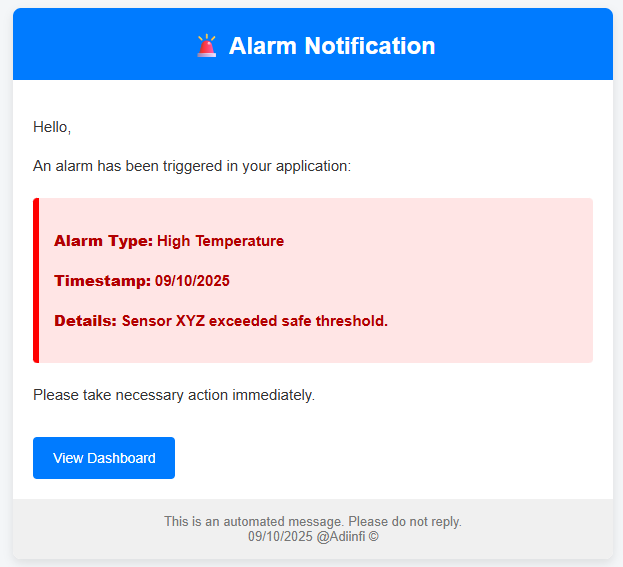

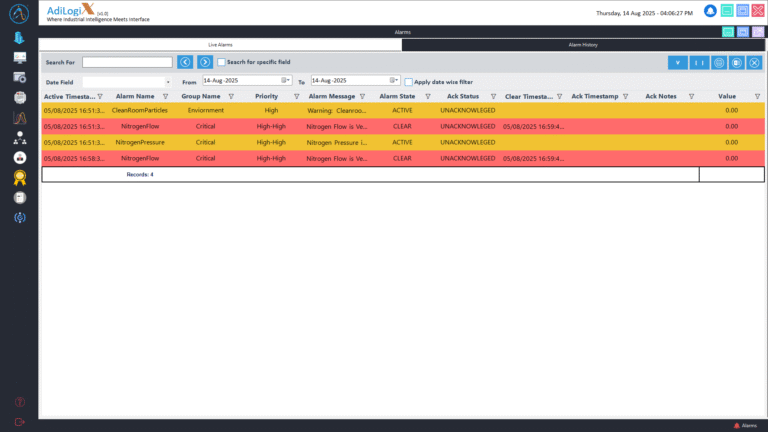

Built-In Alarm Management

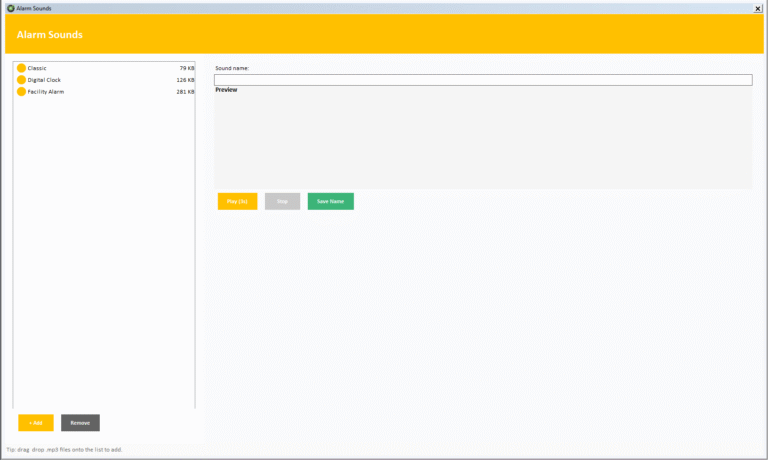

AdiLogix lets you configure alarms in just a few clicks. Select a tag, define thresholds, choose alarm types, and you’re done. View alarms in real-time, track historical events, and stay ahead of critical issues—all without scripting or complex logic. Users can also customize alarm colors for clear visual distinction and faster recognition.

Telegram, WhatsApp, and Email notification support for password policy alerts and alarm notifications. Users will now receive instant updates directly in their inbox, ensuring timely awareness of security and system events.

High-priority alarm processing with full customization for High-High, High, Low, and Low-Low conditions.

Customizable Alarm Sounds.

For Example

Telegram, WhatsApp, and Email Notification Support

Multiple Terminals

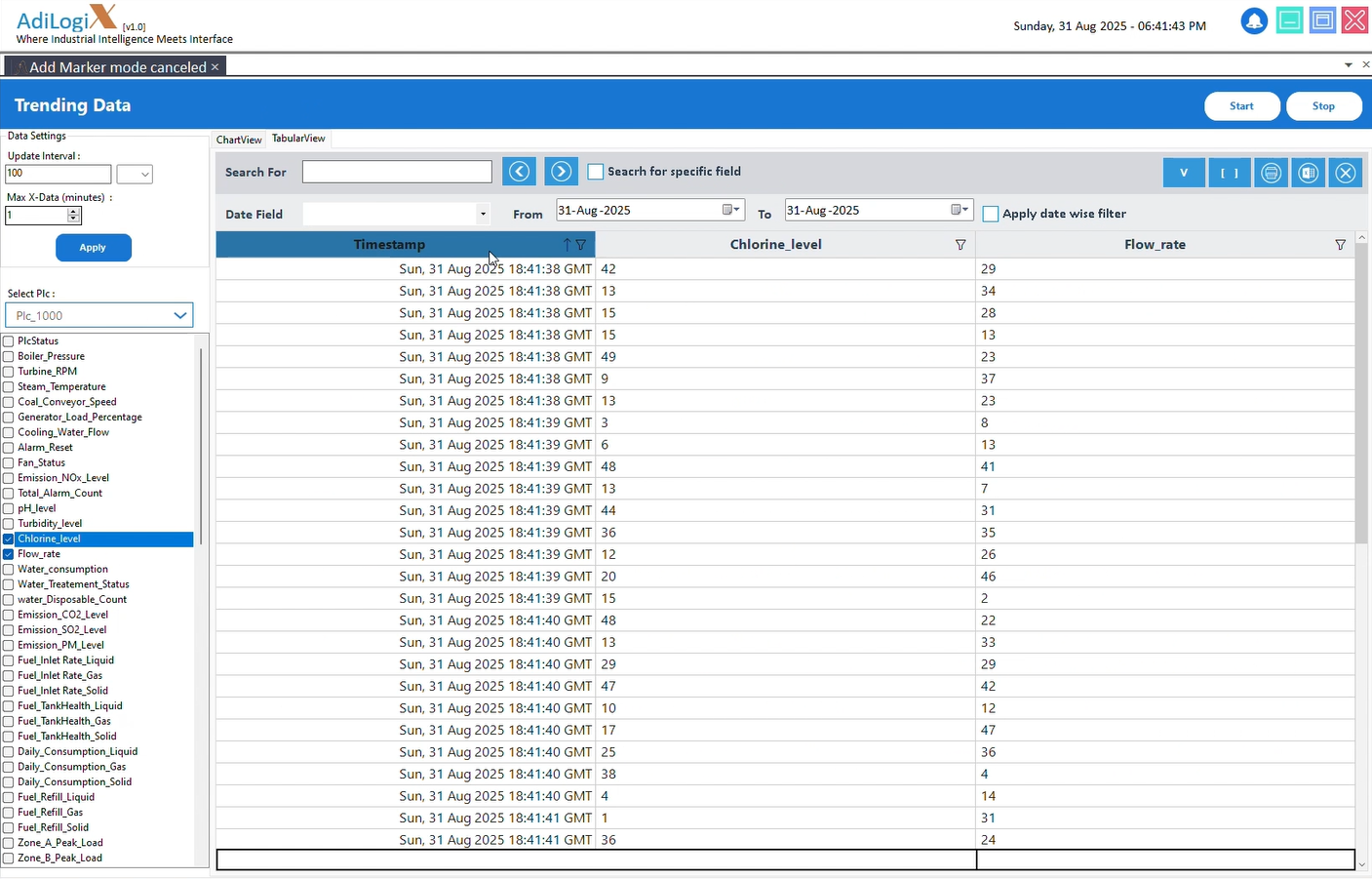

Advanced level Live Trending Chart and Table option

Live Debugging During Designing

AdiLogix provides powerful live debugging tools that let you monitor system behavior, trace errors, and optimize performance without stopping operations. Stay in control with instant visibility into every process.

Debugging industrial automation systems can often be time-consuming, requiring trial-and-error testing or downtime for troubleshooting. AdiLogix simplifies this by offering live debugging capabilities directly within its interface. Engineers can view tag values, alarms, and logic flow in real time, making it easier to identify issues, validate configurations, and optimize system performance while processes are running.

What AdiLogiX Offers

Industrial PCs (IPC) as HMI/SCADA

Deploy AdiLogiX directly on industrial PCs(with/without touch) or any conventional PC for machine-level control and monitoring. Acts as a lightweight HMI or SCADA at the equipment level. Perfect for localized automation and quick deployment.

Departmental SCADA

Ideal for plant departments or production lines. Provides real-time monitoring, alarms, and reporting within a specific area. Enables departmental teams to operate independently while still integrating with the larger plant.

Enterprise-Wide SCADA Solution

Scale across the entire plant or multiple sites. Unified monitoring of all equipment, utilities, and processes. Cloud-ready for centralized dashboards, analytics, and remote access.

IIoT-Enabled Smart Operations

Connect with IoT sensors, gateways, and edge devices. Provides advanced analytics, predictive maintenance, and AI-driven insights. We support customized Integration with ERP/MES systems for smart factory transformation.

Features

Adilogix provides comprehensive and marketleader features

AdiLogiX SCADA Components

QR Code

A two-dimensional code storing more data, used in SCADA for instant access to manuals, status pages, and maintenance information.

Read More.

Barcode

A machine-readable code with parallel lines, used in SCADA for quick identification, inventory, and asset tracking. Common types include Code 128, Code 39, ITF, and PDF417 for various labeling and data storage needs.

Read More.

Gauges

Gauges in SCADA systems include linear gauges, radial gauges, and digital gauges, which display real-time process values in easy-to-read visual formats, enabling quick status assessment.

Read More.

Buttons

Buttons like toggle buttons, radio buttons, and standard push buttons allow operators to trigger actions, switch modes, and control processes with ease.

Read More.

Boxes

Boxes including text boxes, combo boxes, and list boxes enable user input, data entry, and selection from predefined options, improving interaction with the system.

Read More.

Charts

Charts such as pie plots and multi-plots provide data visualization for trends, comparisons, and performance monitoring, making analysis more efficient.

Read More.

Industries we serve

Pharmaceuticals

Adilogix ensures process control, regulatory compliance, and traceability by monitoring batch operations, critical parameters, and system alarms in real time.

Oil & Gas

Adilogix supports pipeline and tank farm monitoring, pressure control, and remote diagnostics—ensuring secure access and intelligent alarm response for critical assets.

Water & Wastewater

Adilogix enables real-time control of pump stations, tank levels, chemical dosing, and leak detection—ensuring safe and efficient water treatment and distribution.

Industrial Automation

Adilogix connects seamlessly with PLCs to track production metrics, optimize workflows, and deliver real-time visibility into machines and plant performance.

Data Centers

Adilogix monitors environmental conditions, power usage, cooling systems, and backup generators in data centers—delivering real-time alerts and centralized control for uninterrupted IT operations.

Logistics

Adilogix supports monitoring and control of infrastructure such as tunnels, traffic signals, weighbridges, and smart warehouses—improving safety, operational efficiency, and real-time situational awareness across logistics networks.

Semiconductor

Adilogix monitors cleanroom conditions, wafer fabrication equipment, and utility systems—delivering real-time control, traceability, and alerts to ensure precision manufacturing and compliance in semiconductor fabs.

Automotive

Adilogix supervises assembly lines, robotic systems, paint booths, and energy usage—enabling centralized control, predictive maintenance, and quality assurance across automotive production plants.

🖥️ System Requirements

- Operating System: Windows 10/11 (64-bit), Windows Server 2019/2022

- Processor: Intel i3 or higher (multi-core recommended)

- Memory (RAM): Minimum 4 GB (8 GB+ recommended)

- Storage: Minimum 20 GB free disk space (SSD preferred)

- Graphics: Good to have standard DirectX support for HMI/SCADA visualization

🌐 Connectivity & Protocols

Native Protocols: Modbus TCP/IP, RS-485(ASCII/RTU), OPC UA, Siemens S7, Omron FINS, and MQTT Gateways, BACnet, REST API

Custom Protocols: Integration available on demand (based on project size)

IIoT Integration: On demand supports of cloud connectivity (Azure, AWS, private cloud) based on project size

Edge Device Support: Compatible with gateways and industrial IoT devices

🏭 Deployment Options

Industrial PCs (IPC) – Machine-level HMI/SCADA

Standalone HMI – You can use PC as HMI and no need to havetouch based HMI

Smart PLC/HMI: You can directly use IO card or sensor and write whole logic to AdiLogix and no need to have PLC or HMI for automation

Departmental SCADA – Area or line-wise monitoring

Enterprise SCADA – Full plant or multi-site deployments

Cloud/Hybrid – Remote monitoring and IIoT integration

🗄️ Database & Storage

-

Supported Databases: Microsoft SQL Server

-

Data Logging: High-frequency logging from 100 ms onwards

-

History Management: Long-term storage with compression support

-

Backup & Restore: Automated scheduling with encryption support

🔒 Security & Compliance

Standards: FDA 21 CFR Part 11 ready

Audit Trails: Automatic, secure, and detailed tracking

User Management: Role-based access control (multi-user, multi-terminal)

Two Way Aututhentication: OTP based authentication without internet access.

Encryption: Secured and encrypted project files. Secured database SQL server

On Premise Data

Benifits Of Using AdiLogiX

Competitive Pricing Models

AdiLogiX offers flexible and scalable pricing designed to fit businesses of all sizes — from small machine-level automation to enterprise-wide SCADA deployments.

Desktop Based

Robust, high-performance desktop client for critical industrial environments requiring reliable local control.

Universal Platform

Designed to integrate with a wide range of industrial systems and protocols — enabling centralized monitoring and control across diverse equipment and processes.

Rapid Development

Object-oriented design and reusable templates drastically reduce engineering time and maintenance effort.

Built on Trusted IT standards

Modbus tcpip rs485 support

Industry-Leading Support

The industry’s best tech support and solution

FAQ

What is an On-Premise SCADA system?

An On-Premise SCADA system is an industrial automation platform installed locally on plant or enterprise servers for real-time monitoring and control. AdilogiX On-Premise SCADA provides secure, high-performance data acquisition, visualization, and process control without relying on cloud connectivity.

How does an On-Premise SCADA system work?

It collects data from PLCs, RTUs, sensors, and industrial devices through communication protocols, then converts it into graphical dashboards, alarms, and reports. AdiLogiX enables seamless device connectivity, real-time processing, and centralized operational visibility.

Can users access the SCADA system remotely?

Secure remote access is possible via AdiRMS-VPN or web interfaces. AdiLogiX enables authorized remote monitoring while keeping core data stored within on-premise infrastructure.

Which industries commonly use On-Premise SCADA systems?

Industries such as manufacturing, power, water treatment, oil & gas, pharmaceuticals, and infrastructure rely on on-site SCADA. AdiLogiX is designed to support multi-industry deployments with customizable dashboards and workflows.

What reporting and data analytics features are available?

On-Premises SCADA systems generate production, energy, downtime, and compliance reports. AdiLogiX offers automated report scheduling, historical trends, and performance analytics for data-driven decision-making.

Is the system scalable for large plants or multiple locations?

Yes. On-Premise SCADA can scale based on tags, users, and facilities. AdiLogiX supports enterprise-level expansion with multi-plant connectivity and centralized monitoring capabilities.

We’re Hear To Help Your Business

Through Creativity, Integrity, and Innovations.

AdiLogiX Case Study

We deliver customized AdiLogiX On Premise SCADA solutions integrated with the AdiNexus IoT Gateway for real-time monitoring and centralized control.

This helps reduce costs, streamline development, and accelerate time to market.

CNC Machine Monitoring Using Ethernet-Ip

This case study shows how CNC Machine Monitoring enables centralized monitoring of machine performance, production status, energy usage, tool health, and downtime to improve efficiency and productivity.

Smart Hospital BMS

This case study shows how BACnet-based Smart Hospital BMS enables centralized monitoring of HVAC, energy, lighting, and safety systems for efficiency.

Water Treatment Case Study – Secure On-Premise, Long-Distance Monitoring with AdiLogiX MQTT

This case study highlights how AdiLogiX SCADA with native MQTT support enables secure, on-premise, real-time monitoring of water treatment across long distances—without relying on cloud platforms—ensuring reliability, data security, and operational efficiency.

Water Station

AdiLogiX SCADA integrates PLCs, sensors, and control systems in water stations, offering real-time monitoring, secure data handling, and centralized visibility for optimized operations and reduced downtime.

Pharmaceutical

At AdiInfi, we recognize that flexibility and compatibility are key components of successful industrial automation.

Power Plant

How AdiLogix SCADA can transform a power plant plant into a future-ready smart factory

pharmaceutical– Smart, Compliant, and Connected SCADA

At AdiInfi, we recognize that flexibility and compatibility are key components of successful industrial automation.

News

EtherNet-IP Protocol Support for SCADA – AdiLogiX 2.5.0 Release

AdiLogiX 2.5.0 introduces EtherNet-IP protocol support, enabling seamless communication with PLCs and industrial automation systems. This update enhances real-time data exchange, improves connectivity, and simplifies plant monitoring and control.

AdiLogiX 2.4.0 Release – BACnet Protocol Support for SCADA & Building Automation

AdiLogiX 2.4.0 introduces BACnet protocol support, enabling smooth communication with SCADA and building automation systems. This update helps optimize operations, improve connectivity, and simplify facility monitoring.

AdiLogix 2.3.0 Unifies traditional PLCs control and modern MQTT-driven IIoT — in one powerful SCADA platform

AdiLogix v2.3.0 introduces unified MQTT integration across the platform, enabling seamless device connectivity, real-time data visualization, and consistent history and alarm management. This release also delivers enhanced system reliability, performance optimizations, and improved user experience for stable, scalable industrial operations.

Omron FINS & Siemens S7 Connectivity-AdiLogix 2.2.0

Version 2.2.0 expands platform capabilities with complete Omron FINS and Siemens S7 PLC integration, unified tag handling, real-time trending, and improved data processing reliability.

AdiLogix 2.1.0 – Latest Enhancements & Updates

Unveiling AdiLogix v2.1.0—more intelligent, connected, and automated than ever. With real-time WhatsApp/Telegram messaging, role-based alarms, advanced tag insights, automatic report generation, and a highly optimized performance core, AdiLogix 2.1.0 delivers smarter control and unmatched efficiency across your industrial ecosystem.

AdiLogiX OPC UA Integration V2.0.0

Introducing AdiLogiX v2.0.0 — smarter, faster, and more connected.

Now with full OPC UA integration, enhanced performance, and powerful new tools that bring secure, intelligent control to every level of your operation.

Unveiling AdiLogiX V1.1.0

We’re excited to unveil Adilogix V1.1.0 SCADA / HMI— a step forward in intelligent industrial control with one-click reporting, custom data formats, and advanced backup and restore support.